This article was based on my invited presentation at the Research Topical Symposium (RTS) – “Environmentally Assisted Cracking” held at the NACE International CORROSION 2015 conference in Dallas, TX, USA and published in a special issue of CORROSION Journal – Vol. 72, Issue 7 (July 2016), 2015 Research Topical Symposium Proceedings – “Environmentally Assisted Cracking”. Milos B. Djukic, Gordana M. Bakic, Vera Sijacki Zeravcic, Aleksandar Sedmak, Bratislav Rajicic, “Hydrogen Embrittlement of Industrial Components: Prediction, Prevention, and Models,” CORROSION. 2016;72(7):943-961. doi: 10.5006/1958.

Why is it important?

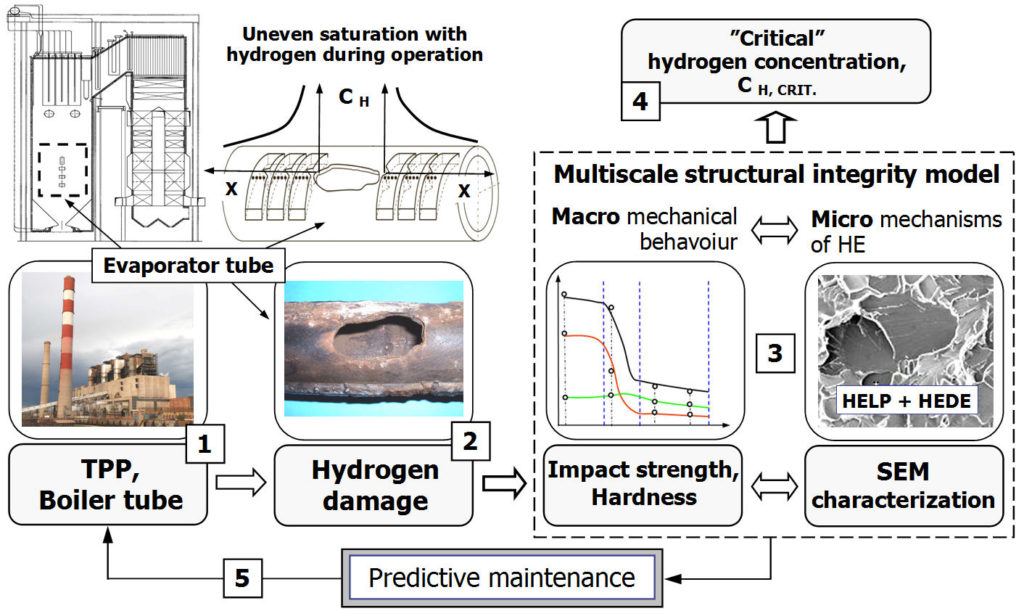

The simultaneous activity and synergistic interplay of the hydrogen-enhanced localized plasticity (HELP) and hydrogen-enhanced decohesion (HEDE) mechanisms of hydrogen embrittlement (HELP+HEDE) was fully confirmed for the first time in low carbon grade 20 – St.20 (or 20G, equivalent to UNS G10200, AISI 1020) steel specimens in situ charged with hydrogen, and not only through simulation and modeling. A background for the analysis of the viable hydrogen embrittlement mechanisms: (HELP+HEDE) in a ferritic-pearlitic carbon steel and development of a model for structural integrity analysis is a literature overview of the current state of the art in hydrogen embrittlement (HE) modeling and studies (140 References), presented in this article. The HELP+HEDE model of HE for structural integrity analysis is based on the correlation of mechanical properties to scanning electron microscopy fractography analysis of fracture surfaces in the presence of simultaneously active HE micro-mechanisms (HELP+HEDE), see Figure 1. This article also gives a broad overview of the scale transitions and different approaches (macro, micro-meso, and nano-atomic) in multiscale HE modeling and study (density functional theory – DFT, molecular dynamics simulation – MD, Monte Carlo simulation – MC, polycrystalline FE, and macro FE), and the related inherent problems (e.g., times scales). Also, the effect of hydrogen on the material mechanical properties and ductile to brittle transition resulting from the concurrent and synergistic or competing action of HELP and HEDE mechanisms of HE was discussed.

Editorial, CORROSION Journal

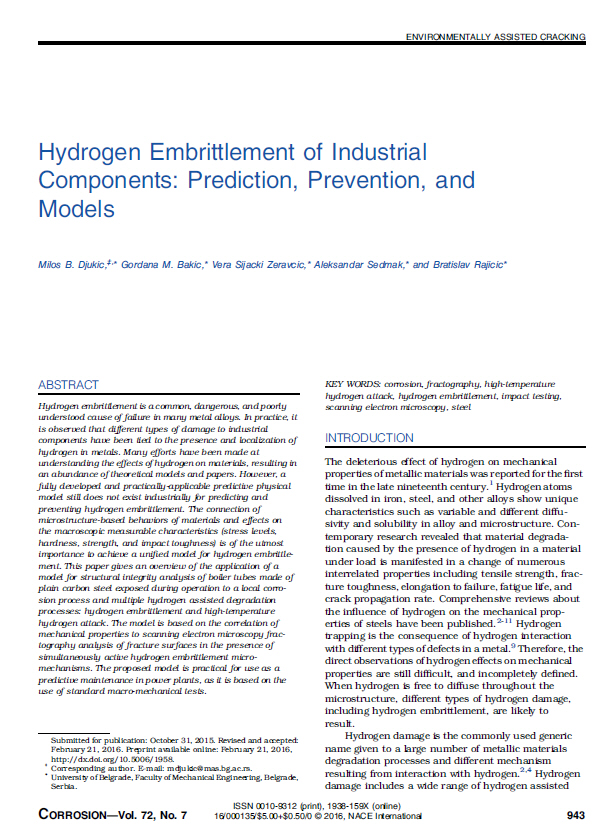

“Professor Milos Djukic, et al., presented a modeling approach that can be applied to industrial boiler tube systems, in a paper titled, “Hydrogen Embrittlement of Industrial Components: Prediction, Prevention, and Models.” This paper focuses on predictive models for the hydrogen embrittlement of plain carbon steels used in industrial boiler systems. Correlations between microstructure, fractographic observations, and macro-mechanical testing data are used to propose a model enabling enhanced predictive maintenance of industrial component systems. Crack formation and growth due to hydrogen embrittlement (HE) and high-temperature hydrogen attack (HTHA) are both addressed.” – from EDITORIAL, CORROSION Journal, Vol. 72, Issue 7 (July 2016), 2015 Research Topical Symposium Proceedings – “Environmentally Assisted Cracking.”

Abstract

Hydrogen embrittlement is a common, dangerous, and poorly understood cause of failure in many metal alloys. In practice, it is observed that different types of damage to industrial components have been tied to the presence and localization of hydrogen in metals. Many efforts have been made at understanding the effects of hydrogen on materials, resulting in an abundance of theoretical models and papers. However, a fully developed and practically-applicable predictive physical model still does not exist industrially for predicting and preventing hydrogen embrittlement. The connection of microstructure-based behaviors of materials and effects on the macroscopic measurable characteristics (stress levels, hardness, strength, and impact toughness) is of the utmost importance to achieve a unified model for hydrogen embrittlement. This paper gives an overview of the application of a model for structural integrity analysis of boiler tubes made of plain carbon steel exposed during operation to a local corrosion process and multiple hydrogen assisted degradation processes: hydrogen embrittlement and high-temperature hydrogen attack. The model is based on the correlation of mechanical properties to scanning electron microscopy fractography analysis of fracture surfaces in the presence of simultaneously active hydrogen embrittlement micro-mechanisms. The proposed model is practical for use as a predictive maintenance in power plants, as it is based on the use of standard macro-mechanical tests.

[altmetric doi=”10.5006/1958″ type=”donut” condensed=”true” data-hide-no-mentions=”false” popover=”right” details=”right”]

Kudos spotlight article (April 2016)

This article was featured in the sixth edition of Kudos Spotlights #6 (April 19, 2016) among the publications that have recently had high interest.

CORROSION Journal – Top 20 most searched and viewed articles

This article is amongst CORROSION Journal’s Top 20 (currently at no. 14) most searched and viewed articles (February 2017).

Citation

Milos B. Djukic, Gordana M. Bakic, Vera Sijacki Zeravcic, Aleksandar Sedmak, Bratislav Rajicic, “Hydrogen Embrittlement of Industrial Components: Prediction, Prevention, and Models,” Corrosion. 2016; 72(7): p.943-961. doi:10.5006/1958.

About Prof. Milos Djukic

Prof. Milos B. Djukic is Associate Professor at the University of Belgrade, Faculty of Mechanical Engineering, Materials Technology Department & Welding and Welded Structures Module, Serbia. He writes on topics of materials science, corrosion and hydrogen embrittlement on Hydrogen Embrittlement & Materials Science blog. He is a founder and coordinator of “The Network of Excellence (NoE) in Hydrogen Embrittlement,” which aims to strengthen scientific and technological excellence by developing an integrated and interdisciplinary scientific understanding of hydrogen degradation of engineering materials and their co-evolution with science, materials science, industry, and society. He is also an organizer of the “Serbian Network of Excellence and Research Framework in Materials Characterization – Hydrogen Embrittlement” and ongoing online research project on ResearchGate, titled: “Hydrogen Embrittlement – Understanding and research framework” (currently at 90+members, 270+followers, 4400+reads, 70+updates, 540+references, 6300+Project audience), which refers to the challenges and problems of how to link models and phenomenology of hydrogen-related failures of industrial components at different scales and how to successful translate the insights gained into outcomes of practical value to the engineering community.